Why Can’t Warehouse Automation Wait…

Manual tasks consume half of daily work hours

Labor shortages remain critical

Space constraints hinder growth

The automation wave is gaining ground

Robots are joining the team

Warehouse automation is transforming supply chains worldwide, delivering new levels of efficiency, visibility, and agility. For CIOs, CXOs and CTOs in supply chain and logistics integrating automation with SAP Extended Warehouse Management (EWM) unlocks smarter, faster, and more resilient operations, addressing key pain points like labor costs, inventory accuracy, and real-time visibility.

Warehouse automation refers to the use of technology, including both hardware and software, to automate manual tasks within the warehouse. This includes everything from automated storage and retrieval to AI-driven analytics and real-time data capture.

WhyAutomate?

Modern warehouses face persistent challenges, including:

- Inefficiencies in warehouse operations that slow down order fulfillment and increase costs.

- Inventory inaccuracies lead to overstock, stockouts, and lost sales.

- High labor costs are due to manual, repetitive tasks and reliance on a shrinking labor pool.

- Limited visibility and transparency make real-time decision-making difficult.

How SAP EWM and Warehouse Automation Eliminate the Biggest Pain Points

Warehouse automation powered by solutions like SAP EWM directly address these pain

points:

- Overcomes labor shortages and reduces costs by automating routine work

- Increases inventory accuracy and operational efficiency

- Provides real-time, actionable insights for proactive management

- Enables transparency across the entire warehouse and supply chain

Warehouse automation covers both physical technologies (like robots, AGVs, AMRs, conveyors) and digital tools (like Warehouse Management Systems, and SAP EWM).

AI-Powered Warehouse Management

Artificial intelligence (AI) and machine learning (ML) deliver predictive analytics, demand forecasting, and automated inventory optimization. By leveraging AI-powered warehouse management, companies make smarter, data-driven decisions and reduce out-of-stock or overstock risks.

Core Technologies Enabling Warehouse Automation

Warehouse automation isn’t a one-size-fits-all solution. The right mix of technologies depends on your business needs, warehouse size, and growth plans. Here are the foundational technologies driving modern, high-performing warehouses

Warehouse automation is powered by two complementary technology categories:

digital automation (software-driven control and intelligence) and physical automation (robotics and machinery that carry out warehouse operations). Together, they build a smart, agile, and scalable fulfillment ecosystem.

Digital Automation for Intelligent Control & Integration

Digital automation provides the brainpower of modern warehouses. It orchestrates data, systems, and workflows through:

Smart Warehouse Platforms

Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) coordinate warehouse tasks, equipment, and labor planning. Technologies like SAP EWM take this further by offering advanced orchestration capabilities that bridge digital systems with physical automation across the warehouse.

Predictive Intelligence

Artificial Intelligence (AI) and Machine Learning (ML) deliver predictive analytics, demand forecasting, automated inventory optimization optimize picking routes and detect anomalies before they occur. By leveraging AI-powered warehouse management, companies make smarter, data-driven decisions and reduce out-of-stock or overstock risks.

Connected Data Streams

Internet of Things (IoT) devices track inventory, equipment, and ambient conditions in real-time.

Seamless Software Ecosystems

Integrations with Enterprise Resource Planning (ERP), Transportation Management Systems (TMS), and Order Management Systems (OMS) unlock end-to-end visibility across the supply chain.

Physical Automation for Machines that Move, Sort & Store

Physical automation brings speed, precision, and safety to the warehouse floor with:

Material Handling Systems

Including conveyors, sorters, pick-to-light systems, and Automated Storage and Retrieval Systems (AS/RS) for high-throughput movement and storage.

Mobile Robotics

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) automate transport and picking, adapting to dynamic layouts. To explore real-world ROI, check out our in-depth article on how robotics delivers a $17B supply chain advantage.

Task-Oriented Robotics

Collaborative Robots (Cobots), drones, and robotic arms assist with picking, placing, scanning, or counting tasks.

Voice & Light Guidance

Voice-picking and put-to-light technologies support hybrid human-robot workflows. Together, digital and physical automation form the dual engines of next-gen warehouse performance, tightly orchestrated by SAP EWM.

SAP EWM acts as the digital backbone of warehouse operations by:

- Coordinating automated tasks and real-time workflows

- Integrating with devices like barcode scanners, RFID readers, and robots. See how RFID integration with SAP EWM supercharge warehouse

- Supporting SAP Fiori apps for mobile workforce efficiency

- Enabling real-time inventory visibility and exception handling

SAP EWM Acts as a Central Intelligence Layer for Warehouse Automation

Warehouse orchestration platforms bridge digital intelligence and physical automation enabling real-time control, system integration, and workflow automation. SAP EWM is one such solution that combines real-time data, robotics coordination, and ERP integration into a single intelligent layer for managing complex warehouse operations.

From automating inbound and outbound flows to coordinating barcode scanners, RFID readers, and robotic systems, SAP EWM provides:

- Real-Time Workflow Orchestration across all warehouse zones

- Full ERP Integration with SAP S/4HANA for unified business alignment

- Device & Robot Compatibility including AMRs, AS/RS, and mobile tech

- Mobile-Enabled Analytics via SAP Fiori for on-the-go visibility

SAP EWM brings warehouse automation to life, by moving RFID-tagged pallets through outbound docks with minimal manual work. From staging to loading, everything runs automatically. Real-time EPC Electronic Product Code) scans help track items, improve accuracy, and meet compliance rules. Whether you’re shipping fast or updating your warehouse tech, SAP EWM makes operations smoother and smarter.

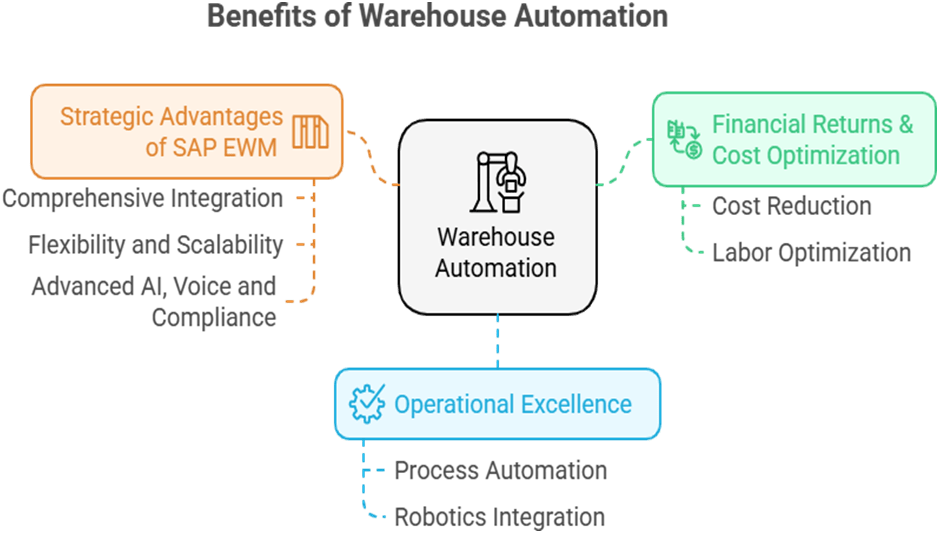

Benefits of Warehouse Automation: Proven ROI and Performance Gains

Warehouse automation delivers measurable value across all dimensions of operations, with most businesses achieving ROI within 18–24 months of implementation and efficiency gains often exceeding 20% approximately.

Financial Returns and Cost Optimization

Cost Reduction and ROI

Companies that invest in automation typically achieve a significant return on investment or more, often within two years of going live. SAP EWM enables real-time inventory visibility, space optimization, and maximized labor utilization, which drives down operational costs and allows for faster capital recovery.

Labor Cost Optimization

Warehouses today are frequently understaffed by 10–25% approximately, with the biggest gaps in material handlers and forklift operators. SAP EWM serves as the backbone for robotic integration, enabling seamless orchestration of automated systems like conveyors and pickers to bridge labor gaps and drive workforce efficiency. See how SAP EWM empowers warehouse operations through advanced automation.

Operational Excellence

Accuracy and Process Automation

Eliminating human error is cited as the top reason for automation according to experts. With SAP EWM, every process step is tracked online, exceptions are flagged and handled in real time, and workflows can quickly adapt to new requirements, driving accuracy, and flexibility.

Robotics and Advanced Automation

SAP EWM enables advanced warehouse automation through robotics integration, which supports task orchestration, real-time robotic performance tracking, and exception handling. It works with mixed fleets from multiple vendors offering flexibility in selecting the right automation tools. As robotic platforms continue to evolve, SAP EWM provides the intelligence needed to align human and machine activity under one operational framework.

Strategic SAP EWM Advantages

Comprehensive integration and Flexibility

You’re never locked into a single vendor or robotics platform. SAP EWM functions as a high-level WMS, delegating automation controls to any WCS or WES. This means maximum flexibility as your automation needs evolve.

Advanced AI, Voice, and Compliance

With features like SAP Joule, workers can interact with SAP EWM using voice or typed queries, simplifying access to data and processes. Built-in compliance features help you track hazardous materials, manage expiration dates, and enforce regulations with automatic audit trails.

Optimizing Warehouse Processes Using SAP EWM

Assess Your Current Operations: Identify key pain points, including inefficiency, errors, high costs, or a lack of visibility. Book an SAP EWM Process Assessment with Stellium’s experts to identify quick wins, optimize workflows, and set your automation strategy on the right track.

Define Automation Goals: Align investments in automation and SAP EWM with your overall business strategy.

Select & Integrate Technologies: Choose the best mix (AS/RS, WMS, AI, robotics) and ensure seamless integration with SAP EWM and ERP systems.

Leverage Advanced Analytics: Use SAP EWM’s analytics to drive continuous improvement and support data-driven decisions.

Partner with Experts: Utilize SAP EWM consulting services for smooth implementation, user training, and maximum ROI. Stellium collaborates with experienced, trusted vendors, an integral part of our global partner ecosystem, enabling us to deliver best-fit solutions to our customers. Get expert help from Stellium.

What’s New in Warehouse Automation and SAP EWM

Warehouse automation and SAP EWM keep getting better with new technology that makes work easier and faster:

Artificial Intelligence & Analytics: Your warehouse can now predict when machines need fixing before they break. It can also guess what products customers will want next month, so you’re always ready with the right items in stock.

Cloud & Internet of Things: Your warehouse can now work from anywhere and grow as big as you need. Small businesses can use the same powerful tools that big companies se, without spending tons of money upfront.

Mobile Robots & Smart Vehicles: These robots can move around your warehouse by themselves, carrying heavy boxes and helping workers stay safe. They’re smart enough to avoid bumping into people and can learn new routes on their own.

Complete Digital Automation: From the moment a customer places an order online until it arrives at their door, everything happens automatically. This means faster delivery, fewer mistakes, and happier customers.

Stellium Implementation Expertise and Results Across Industries

Stellium stands out as a trusted Warehouse Automation and SAP EWM implementation partner, delivering tailored solutions that drive measurable results for global clients across industries. Our industry specialists ensure seamless integration and minimal disruption, optimizing inventory flows, reducing downtime, and integrating production schedules in manufacturing; enhancing just-in-time (JIT) delivery and streamlining parts management in automotive; and improving inventory visibility, fulfillment speed, and management of perishable goods in retail and FMCG to name a few.

Strength of Our Partner Ecosystem

Our robust partner ecosystem significantly amplifies the value we deliver. By collaborating closely with industry leaders in automation technology, including robotics providers and IoT specialists, we ensure our SAP EWM implementations leverage cutting-edge capabilities.

Our recent partnership with Roboteon and Hytek brings an SAP-certified multi-agent orchestration platform for robotics to our clients, accelerating AI/ML-powered warehouse automation. Learn more Roboteon and Stellium’s collaboration and Hytek and Stellium join forces.

Why This Matters for Your Business

These new technologies help your warehouse run smoother, keep workers safer, and make customers more profitable.

Contact us today to automate, optimize, and future-proof your warehouse operations with a tailored SAP EWM solution. Learn more about warehouse automation and begin your journey to warehouse excellence!