Authored By: Stellium’s Supply Chain Planning & Business Consulting Team, Verified by Anirban Majumdar and Vishnu Raj Varma

A global consumer goods company operating in over 80 countries recently rethought its approach to demand planning.

Like many businesses, it relied on traditional forecasting to plan weeks and months using historical sales data, promotional calendars, and statistical models.

But when the market started shifting faster than the plans could keep up – driven by unpredictable consumer behavior, channel volatility, and real-time disruptions, it became clear something was missing.

They didn’t just need to plan for the future. They needed to sense it.

This realization highlights a fundamental shift happening across industries today. While traditional demand forecasting remains crucial for strategic planning, it’s no longer sufficient on its own. Modern supply chains require a dual approach – one that combines the strategic foresight of forecasting with the immediate responsiveness of sensing. Understanding the distinction between these two approaches, and more importantly, how they work together, has become essential for any organization serious about staying competitive in today’s volatile market.

What’s the Difference between Demand Forecasting and Demand Sensing?

Demand forecasting is about projecting what’s likely to happen. It’s built on trends, seasonality, and past performance. It’s essential for strategic planning, budgeting, and long-term supply decisions.

Demand sensing is about identifying what’s happening right now. It uses real-time data like POS transactions, shipments, and customer orders to detect short-term shifts and adjust plans accordingly.

Here’s a simple breakdown:

| Demand Forecasting | Demand Sensing | |

| Time Horizon | Weeks to months | 1 to 14 days |

| Data Sources | Real-time POS, shipment, and external signals | Real-time POS, shipment, external signals |

| Update Frequency | Weekly or monthly | Daily or hourly |

| Use Case | Budgeting, production planning | Replenishment, supply response |

| Strength | Long-range visibility | Real-time responsiveness |

Companies need both. Forecasting helps set the course. Sensing helps stay on it when the road bends.

After adopting an integrated planning solution, this CPG giant saw:

- 30% improvement in forecast accuracy

- 20% reduction in inventory (without harming service levels)

- Real-time visibility across global, regional, and local teams

- Faster scenario simulations and supply chain responsiveness during demand surges

They didn’t throw out their forecasts. They augmented them with sensing, enabling the business to react faster, plan smarter, and reduce waste.

How SAP IBP Enables Both Demand Forecasting and Demand Sensing

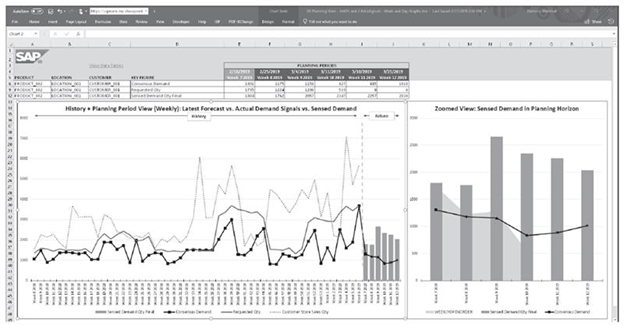

SAP Integrated Business Planning (IBP) brings demand forecasting and demand sensing onto a single platform – with powerful analytics, AI/ML-based models, and cross-functional visibility.

With SAP IBP, companies can:

- Build long-term forecasts based on historical trends, promotions, and market assumptions

- Ingest real-time data feeds from POS systems, distribution centers, or customer orders

- Update short-term projections daily (or even hourly)

- Simulate what-if scenarios (e.g. promotions, demand spikes, supply delays)

- Align demand, supply, and finance teams with a unified planning view

The result is a supply chain that doesn’t just see demand; it understands and responds to it.

Reference: SAP Press Blog- https://blog.sap-press.com/sensing-short-term-demand-patterns-with-sap-ibp-and-machine-learning

Strategic Competitive Advantage of Combined Forecasting and Sensing

This shift from static forecasting to a combined forecasting + sensing approach isn’t just technical; it’s strategic. It’s about how your supply chain behaves when demand doesn’t follow the script. Organizations that integrate forecasting and sensing don’t just react faster – they avoid lost sales, reduce waste, and capture demand others miss. When demand moves, they’re already in motion.

In today’s market, planning is no longer a back-office function. It’s a growth lever.

Read the full guide on mastering SAP IBP planning to explore key planning modules and AI-powered capabilities. And see AI and ML enhancing demand forecasting with SAP IBP & BTP, and learn how intelligent technologies drive accuracy and smarter supply chain decisions.

Unify and Evolve Demand Planning with SAP IBP Expertise

Bring forecasting and sensing together with expert-led agile planning drives real results. From real-time sensing to predictive forecasting, Stellium empowers your team to plan smarter, act faster, and stay resilient. Explore our end-to-end SAP IBP solutions and get expert-led SAP IBP implementation support. Talk to us!