In today’s rapidly evolving manufacturing sector, data is no longer just a byproduct of operations, it’s the lifeblood of innovation. Legacy systems like SAP Manufacturing Integration and Intelligence (SAP MII) have long served as pillars for integrating shop-floor data with enterprise systems. However, as Industry 4.0 accelerates, manufacturers face mounting pressure to adopt agile, future-ready platforms that turn raw data into real-time, actionable intelligence. Enter SAP Digital Manufacturing (DM), a next-generation solution designed to modernize IT landscapes, bridge silos, and unlock operational efficiency.

When Should You Transition from SAP MII to SAP Digital Manufacturing?

While SAP MII laid the groundwork for manufacturing analytics, its limitations in scalability, customization, and architecture increasingly hinder modern operations. As an on-premise, NetWeaver-based system, SAP MII’s performance heavily depends on system configurations, leading to inconsistent real-time data processing. This gap forces manufacturers to rely on additional tools for advanced execution capabilities.

In contrast, SAP DM is built natively for the cloud era. It eliminates SAP MII’s hardware-dependent scalability constraints, offering elastic computing to adapt to fluctuating production demands. Unlike SAP MII’s high total cost of ownership, driven by on-premise infrastructure and maintenance, SAP DM reduces costs through cloud-native efficiency and pre-configured workflows. Moreover, SAP DM is SAP’s strategic focus for manufacturing, whereas SAP MII’s roadmap is gradually being phased out in favor of modern alternatives.

Bridging the Gap by Enabling Real-Time Insights and Quality Focus

Dynamic Dashboards and Real-Time Monitoring

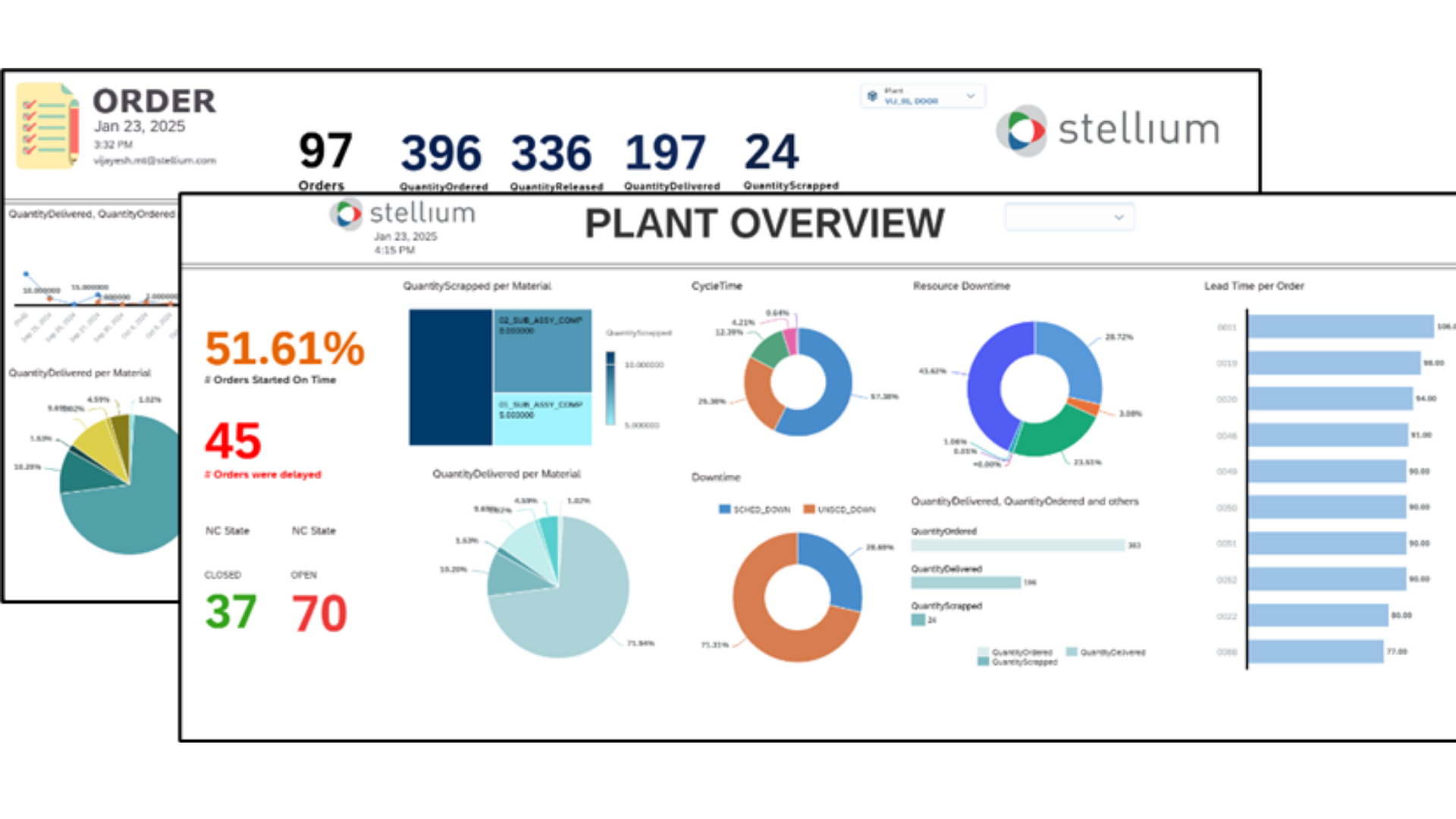

While SAP MII supports real-time data processing, its performance hinges on system configurations, often resulting in increased latency during peak loads. SAP DM, however, optimizes high-speed data processing through its cloud-native architecture. A key highlight of SAP DM is its capability to collect real-time data directly from execution processes and store it in the Manufacturing Data Object (MDO). This centralized repository ensures that all production data, be it related to scrap rates, cycle times, lead times, or machine utilization, is readily available and structured for analysis. What sets this system apart is its flexibility, possibility to define custom formulas and calculations tailored to the manufacturer’s specific requirements, converting raw data into meaningful metrics.

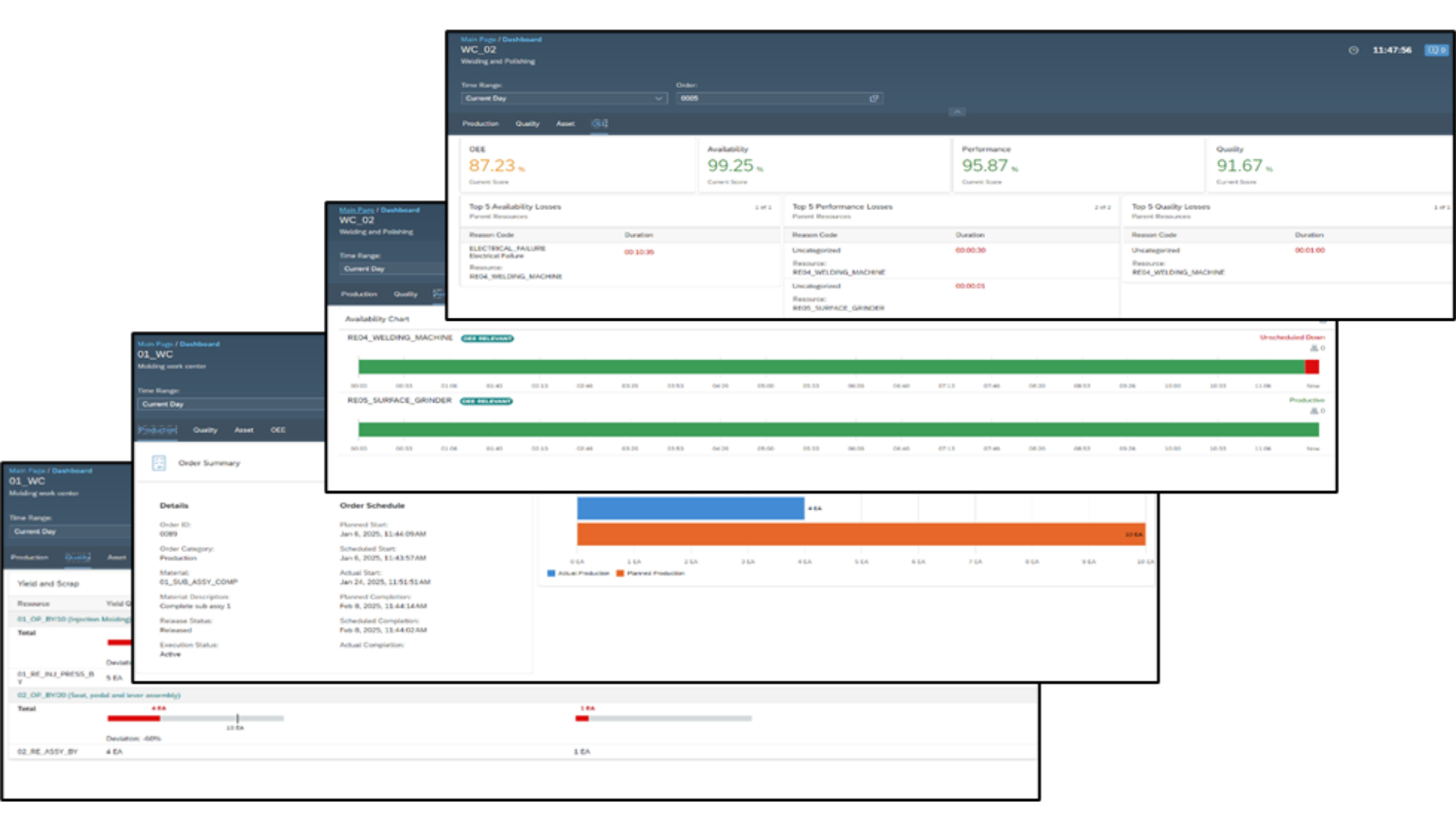

The Line Monitor feature in SAP DM provides a comprehensive, real-time overview of production lines, delivering critical insights into production performance, quality metrics, asset status, and Overall Equipment Effectiveness (OEE). By consolidating data from multiple sources into a single intuitive interface, it allows manufacturers to monitor key parameters such as production output, defect rates, machine availability, and performance efficiency with ease.

In real time, the Line Monitor tracks production counts against targets, highlights quality deviations, and displays the status of assets (e.g., running or down). Additionally, it dynamically calculates OEE, breaking it down into its core components (i.e. availability, performance, and quality) to pinpoint inefficiencies and improvement areas.

With its ability to quickly identify bottlenecks, detect quality issues, and optimize asset utilization, the Line Monitor ensures smoother, more efficient production processes while enhancing overall operational performance.

Closed-Loop Quality and Root-Cause Analysis

SAP DM closes the loop on quality management by linking defects to specific machines, operators, or material batches in real time—capabilities SAP MII could only achieve through third-party add-ons. SAP DM’s root-cause analysis tools correlate downtime events with contextual data (e.g., shift changes or material batches), enabling rapid corrective actions. SAP MII, while robust, lacked this depth of contextual integration, often leaving teams to troubleshoot in hindsight.

Role-Based Insights and Mobility

SAP MII’s user interface, reliant on SAP UI5 and custom JavaScript dashboards, demands significant IT expertise to tailor for diverse roles. SAP DM democratizes data access with a modern, Flori-based UI and mobile-ready dashboards. Frontline workers receive real-time updates on machine status or quality alerts, while executives gain consolidated views of plant-wide KPIs like throughput or on-time fulfillment. This flexibility surpasses SAP MII’s rigid, one-size-fits-all reporting.

Benefits of SAP DM Strategically Future-Proofing Manufacturing Excellence

Adopting SAP DM isn’t merely about replacing SAP MII, it’s about future-proofing operations. The key advantages include:

- Unified Data Ecosystem: Break down silos between production, inventory, and supply chain systems via native integration with SAP S/4HANA and IoT.

- Scalability: Cloud-native architecture ensures elastic scaling, overcoming SAP MII’s on-premise hardware limitations.

- Lower Total Cost of Ownership: Reduce infrastructure and maintenance costs while accelerating ROI with pre-configured workflows.

- Industry 4.0 Readiness: Natively designed for IoT, digital twins, and machine learning, SAP DM outpaces SAP MII’s patchwork approach to emerging technologies.

As SAP DM continues to mature, its role as a catalyst for smart manufacturing will only expand. Manufacturers who adopt this platform today aren’t just upgrading their IT landscapes; they’re securing a vantage point in the data-driven future. The shift from SAP MII to SAP DM isn’t optional, it’s essential for those aiming to lead, not follow, in the next industrial revolution.

In essence, SAP DM transforms manufacturing IT from a cost center into a strategic asset, turning data into the ultimate driver of efficiency, quality, and growth. The future of manufacturing isn’t on the horizon; it’s here, and SAP DM is the key to unlocking it.

To see how next-generation solutions are shaping smart factories, Explore the advancements in SAP Digital Manufacturing (DM).

Learn more from our experts on migrating from SAP MII to SAP DM in our exclusive webinar.