Authored by: Syed Shabbir Ahmad, Stellium DSC Team (Digital Supply Chain Consulting), updated for current use (Source: LinkedIn Stellium Inc)

The transportation industry is constantly evolving, and efficiency targets shift as businesses grow, diversify, and face new operational pressures. Yet across all industries, manufacturing, logistics, retail, consumer goods, and beyond, several universal goals remain the same: reducing transportation costs, lowering carbon footprint, and improving service reliability.

SAP Transportation Management (SAP TM) enables organizations to achieve these goals through advanced planning, optimization, and execution capabilities that help planners design smarter, more efficient transportation plans.

This article explores how SAP TM’s optimizer works, what parameters it considers, and how businesses can leverage it to drive operational excellence.

- SAP TM Overview

- Why Transportation Planning Requires Optimization

- SAP TM Optimizer Planning: How It Works

- Industry Use Case- Customized Optimization for a Paint Manufacturer

SAP TM Overview

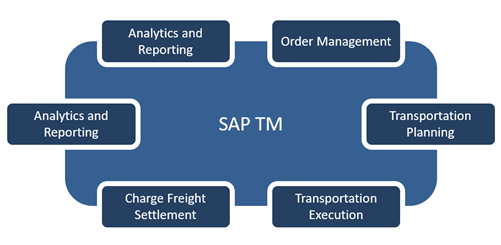

SAP TM provides a complete suite of modules supporting the end-to-end transportation lifecycle:

- Transportation Planning

- Order Management

- Contract & Rate Management

- Charge Calculation & Settlement

- Strategic Freight Management

- Transportation Execution

- Analytics & Reporting

SAP TM Overview

Of these, Transportation Planning sits at the core, the engine that connects business requirements, constraints, and execution rules into a unified transportation plan.

Why Transportation Planning Requires Optimization

Transportation involves many moving pieces – shipment characteristics, routing rules, fleet availability, carrier agreements, delivery commitments, and multi-modal routing.

Across nearly every supply chain scenario, the key areas that require optimization include:

Key Optimization Areas:

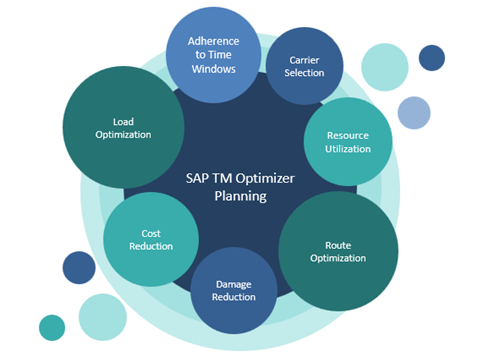

- Route Optimization

- Vehicle & Resource Utilization

- Schedule Optimization

- Load Optimization

- Carrier Ranking & Selection

Optimizing these parameters leads directly to:

- Reduced transportation cost

- Lower fuel consumption & carbon footprint

- Reduced damages

- Faster warehouse and dock turnaround

- Improved customer service levels

- Higher overall efficiency

SAP TM Optimizer Planning: How It Works

SAP TM Optimizer Overview

Unlike simple routing scenarios such as the classic Travelling Salesman Problem (TSP), real-world transportation planning must consider dozens of variables simultaneously.

SAP TM handles these complexities through a powerful Optimizer Engine supported by modular components.

SAP TM Optimizer Components

TVSR – Vehicle Scheduling and Routing

Build executable plans by selecting the best vehicle, route, and schedule.

TVRG – Transportation Proposal

Provides alternative plans for planners to compare and choose from.

TSPS – Carrier / Service Provider Selection

Selects the best carrier based on ranking, share distribution, or custom logic.

TSFM – Strategic Freight Management

Supports long-term capacity, procurement strategy, and freight management processes.

TVSO – Load Optimization

Builds optimized loads based on stacking logic, LIFO rules, compatibility, and equipment constraints.

What the SAP TM Optimizer Considers During Planning

To generate the most efficient transportation plan, SAP TM evaluates multiple operational and business constraints simultaneously. These constraints ensure that the optimizer produces a solution that is both executable and aligned with real-world requirements.

1. Resource Constraints

These rules determine whether a vehicle or piece of equipment is suitable for a given shipment.

- Available vehicles and equipment

- Capacity limits (weight, volume, pallet positions)

- Minimum utilization thresholds required by the business

2. Schedule and Delivery Constraints

SAP TM ensures that all plans respect customer commitments and operational timelines.

- Requested pickup and delivery time windows

- Maximum allowable stops per route

- Transshipment and cross-docking rules

3. Load Planning Constraints

These constraints ensure that loads are built safely, efficiently, and according to product-handling requirements.

- LIFO (Last In, First Out) rules

- Stackability limitations

- Weight distribution and axle load considerations

- Height and dimensional restrictions

4. Compatibility Rules

SAP TM checks compatibility conditions to prevent unsafe or impractical combinations during planning.

- Product–product incompatibilities (e.g., chemicals, food, hazardous goods)

- Product–vehicle incompatibilities (e.g., refrigerated vs. non-refrigerated cargo)

5. Cost Model & Decision Variables

SAP TM uses cost-based decision logic to identify the most efficient transportation plan.

- Least-cost routing based on tariffs, contracts, or negotiated rates

- Least-distance routing depending on operational preferences

- Penalties for late delivery, under-utilization, or constraint violations

These inputs help the optimizer produce transportation plans that respect constraints while minimizing cost and maximizing utilization.

Industry Use Case- Customized Optimization for a Paint Manufacturer

For a global paint manufacturer, Stellium finetuned SAP TM’s optimizer to reflect unique business needs:

Damage Reduction: Limits on stacking and handling

Ground Operations Efficiency: Balancing full vs. partial pallets

Minimum Truck Utilization: Preventing inefficient dispatches

Maximum SKU Threshold: Avoiding overly complex loads

Demand-Based Prioritization: Picking critical orders first

The result:

Improved truck loading efficiency, fewer damages, better warehouse operations, and reduced transportation costs. The successful SAP TM implementation at Kirloskar Brothers Limited demonstrates how Stellium delivers practical, future-ready transportation solutions that enhance visibility, streamline operations, and accelerate digital transformation.

Read and download the Case Study here

SAP TM Delivers Value Across Sectors

SAP TM’s flexible rule framework allows the optimizer to adapt to the unique planning challenges found in diverse industries such as:

- Apparel and Fashion – high SKU variability, frequent small shipments

- Logistics Service Providers (3PL/4PL) – multi-client operations and complex routing

- Pump and Industrial Manufacturing – heavy, oversized, or fragile cargo

- Chemicals & Paints – strict safety rules, incompatibility handling, and damage reduction

- Fresh Produce and Food – temperature-controlled transport and time-sensitive delivery

- Automotive – just-in-time sequencing and multi-plant coordination

- Retail & Distribution – large volume, high-frequency replenishment cycles

Every industry has unique transportation challenges – SAP TM allows planners to model constraints and create executable, optimized transportation plans that fit their business reality.

Conclusion – Optimization Is Continuous Capability

Creating an optimized transportation plan is not a one-time exercise, but an ongoing capability that depends on accurate data, well-defined business rules, intelligent scheduling, and continuous tuning over time. SAP TM brings all these elements together, enabling organizations to plan faster, operate smarter, and continuously refine their transportation strategies for maximum efficiency.

Stellium’s SAP TM solutions help organizations design, configure, and scale advanced planning frameworks that deliver measurable cost savings and operational excellence.

👉 Book a consultation with our SAP TM team. Read the Original Stellium LinkedIn Article- (21) Creating Optimized Transportation Plans with SAP TM | LinkedIn