Authored By: Anoop Prasad, Associate Director – Digital Manufacturing at Stellium Inc

Real-time batch visibility, embedded quality, and scalable execution are no longer optional in process manufacturing.

This article shares how SAP Digital Manufacturing was implemented in a live plant — and the practical takeaways process manufacturers should consider before starting their own journey.

What is SAP Digital Manufacturing Implementation in Process Industries

Business Challenges Before SAP Digital Manufacturing Implementation

Why SAP Digital Manufacturing is Ideal for Process Industry Plants

SAP Digital Manufacturing Architecture for Process Industry Implementation

Stellium’s SAP DM Accelerators for Process Industry

What is SAP Digital Manufacturing Implementation in Process Industries

Digital Manufacturing is often discussed in presentations, roadmaps, and strategy decks. But the reality of implementing SAP Digital Manufacturing (SAP DM) in a live factory environment is very different from theory.

Having worked on SAP implementations for many years, I recently led a full SAP Digital Manufacturing implementation in a real production environment. This blog shares practical lessons learned from the shop floor – what worked, what didn’t, and what I would strongly recommend to anyone planning an SAP DM rollout.

This is not a product overview. This is an implementation story.

Business Challenges Before SAP Digital Manufacturing Implementation

Like many manufacturing organizations, the plant faced challenges that were familiar but costly:

1. Implementation & Operational Complexity

Plant construction was running parallel to implementation

Scratch up implementation based on business process assumptions from the existing plant.

High volume production with a high availability system expectation

Scaling difficulties limited the ability to expand operations smoothly

2. Visibility & Decision-Making Gaps

Delayed issue detection on quality and material shortages

Heavy dependency on supervisors for updates

Limited real-time visibility reduced proactive decision-making

Lack of milestone tracking led to difficulties in ensuring process integrity

3. Process Inefficiencies & Quality Risks

Manual processes led to inefficiencies and human error

Formulation inconsistencies led to quality variation across batches

Portioning inaccuracies caused waste and reduced profitability

Inventory mismatch between ERP and Shop Floor

4. Integration & Logistics Challenges

Shop Floor Scale integration – key requirement for critical business processes during production

Inefficient packing and logistics increased risk of damage

The existing systems captured data, but not at the speed or granularity required for modern manufacturing operations.

The business goal was clear: Move from reactive reporting to real-time, execution-level visibility – without disrupting production.

Why SAP Digital Manufacturing is Ideal for Process Industry Plants

The question was not whether to digitize manufacturing, but how.

SAP Digital Manufacturing was selected because:

- Native integration with S/4 Process Manufacturing (PP/QM)

- Strong support for batch-oriented execution and 100% digital traceability from raw materials to finished products

- It provides execution, visibility, and analytics on one platform

- It enables a cloud-first manufacturing architecture

- Strong integration capability with the shop floor devices

Most importantly, SAP DM allowed us to standardize core execution processes while still supporting plant-level realities.

Learn how organizations are transforming process manufacturing with SAP Digital Manufacturing.

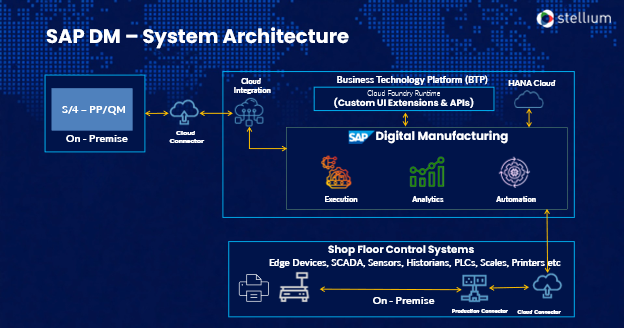

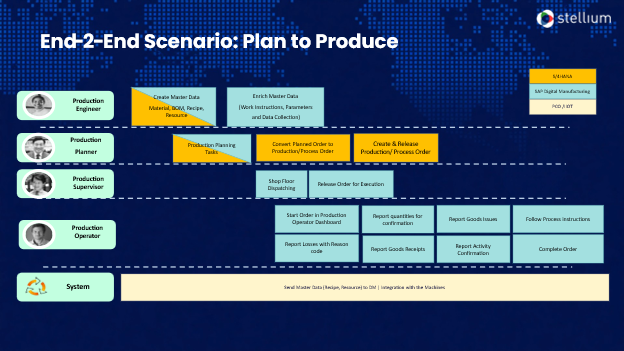

SAP Digital Manufacturing Solution Architecture for our Process Customer

At a high level, the landscape consisted of:

- SAP S/4 – PP/QM (On-Premise)

- Process orders

- Master data

- Goods movements

- SAP Digital Manufacturing (Cloud)

- Order execution

- Operator workflows

- Real-time Activity & Quantity confirmations, Goods Issue, Goods Receipts

- Quality and production visibility

- Shop-floor devices & integrations

- Operator terminals

- Mettler Toledo Scales

- Barcode Scanner

Data flow (simplified):

- Process orders created in S/4

- Orders replicated to SAP DM

- Execution and confirmations performed in SAP DM

- Data captured from the scale interface into SAP DM

- Actuals posted back to S/4 in near real time

The key success factor was keeping the architecture simple and resilient.

Stellium’s SAP DM Accelerators for Process Industry:

While SAP Digital Manufacturing provides a strong standard foundation, real process industry operations often require additional execution controls and operator-centric enhancements.

During the implementation, we leveraged a structured set of 11 accelerators focused on the following areas that added business value to the final implemented solution:

SAP DM Accelerators for Process Industry Implementation

| # | Accelerator | Primary Focus Area | Ensures precise dosing, reduces manual errors, and improves batch consistency |

| 1 | Digital BOM-Based Mixing via Integrated Scale | Batch Mixing & Portioning | Role-based validation aligned with the order lifecycle |

| 2 | Supervisor Approval for Batch Corrections | Compliance & Governance | Controlled deviation handling with full audit traceability |

| 3 | QR-Based Material, Batch & Scale Selection | Operator Efficiency | Faster execution and reduced manual entry errors |

| 4 | FEFO-Based Batch Validation & Consumption | Inventory Control | Prevents expired material usage and improves stock rotation |

| 5 | Performance-Driven Portioning Controls | Quality & Accountability | Adaptive tolerance control and operator performance safeguards |

| 6 | Milestone-Based Phase Automation | Execution Synchronization | Automated phase confirmations and real-time S/4 integration |

| 7 | Digitally Controlled Filling & Consolidated Consumption | Shop-Floor Execution | Guided portioning with minimal system interaction overhead |

| 8 | Integrated Packing & Traceability | End-to-End Genealogy | Full pack/unpack tracking and automated labeling |

| 9 | Real-Time Operational Dashboards | Visibility & Analytics | Live KPI monitoring for proactive decision-making |

| 10 | Enhanced Post-Production Reporting Controls | Data Governance | Role-based validation aligned with order lifecycle |

| 11 | Advanced Confirmation & Goods Receipt Enhancements | Execution Accuracy | Validated reporting with role-based operational control |

To explore how these industry-ready templates extend standard SAP Digital Manufacturing capabilities, read about Stellium’s 11 SAP DM accelerators for process manufacturing

Business Results from SAP Digital Manufacturing Implementation

Post go-live, the business started seeing measurable improvements:

- Real-time batch visibility and controlled material consumption

- Reduced execution errors through guided portioning workflows

- Stronger end-to-end traceability from raw material to packed goods

- Faster deviation detection and response

- Improved operator productivity and accountability

- Enhanced compliance readiness and audit confidence

Most importantly, the combination of standard SAP DM capabilities and targeted accelerators created a scalable digital execution framework tailored for process manufacturing.

Key Lessons from a Real SAP Digital Manufacturing Case Study

Here are the practical implementation lessons that mattered most:

- Start with business problems, not features

- Keep the architecture simple

- Respect the shop-floor reality

- Invest early in master data quality

- Treat change management as a core workstream

SAP Digital Manufacturing is powerful – but only when implemented with discipline and empathy for operations.

Want to explore the full implementation journey? Read the detailed SAP Digital Manufacturing case study and download the complete success story.

Final Insights on Implementing SAP Digital Manufacturing Successfully

Digital Manufacturing is not a one-time project.

It is a capability that evolves with the business.

SAP DM provides a strong foundation, but success depends on how thoughtfully it is implemented.

If you’re planning your SAP Digital Manufacturing journey, explore the SAP DM solutions overview and download the detailed brochure to understand capabilities, architecture, and implementation approaches, and talk to our experts.