Authored by Shamshul Arfin, formerly part of Stellium’s Supply Chain Planning & Business Consulting, verified and updated by the current team.

SAP DM is revolutionizing shop floor efficiency through TDO (Target Dynamic Optimization). Let’s dive into how this game-changing approach is transforming operations and delivering unmatched results for businesses.

I. Focusing our next level operational excellence with AL and ML enabled TDO

In the constant scenario of data-based decision-making through Machine Learning (ML) based on agile model is one of the efficient ways of making unbiased decisions. Stellium is one of the Pioneer organizations to continuously innovate production processes digitally and implement them for our customers for increasing production effectiveness and efficiency. Target Dynamic Optimization (TDO) is a powerful framework that combines algorithms and logic to dynamically adjust tolerance levels based on real-time data and operator behavior. While its core functionality relies on deterministic rules and predefined logic, TDO has the potential to evolve into an AI/ML-enabled solution.

II. Stellium’s Smart Technology and TDO Solutions for Saudi Arabia’s Ar-Raas Region

Stellium recently implemented its TDO solution for a greenfield mega-site project in the region of KSA. This facility, built for manufacturing food products, demonstrates the flexibility and scalability of our TDO logic. Designed as a concept solution, it can be adapted and replicated for other customers, ensuring wide applicability across industries. Adopting TDO empowers manufacturing teams to maintain high accuracy, reduce variability, and streamline processes. It’s a step toward smarter manufacturing—enhancing productivity and sustainability; Ensures Industrial Product Compliance and its Consistency while staying competitive in a demanding market.

1. Unbiased Data based recommendations

2. Historical trend analysis

3. Behavioral review of the operators working on the Shop floor

4. Data optimization based on Operator

5. Efficiency improvement

TDO System and Implementation for Shop floor

Stellium has developed in course of period, for the shop floor operator’s efficiency improvement and analysis developed a process of Target Dynamic Optimization (TDO). The TDO logic integrates Shop floor devices (e.g. Weighing Scales) with SAP Digital Manufacturing solution. The TDO process is developed and validated by integration of Shop Floor Scale – SAP Digital Manufacturing and S4-Cloud Data Base. It uses OPC UA (Open Platform Communications Unified Architecture) interfaces for integration with the Shopfloor weighing scales.

I. Dynamic Weight Scale and Tolerances for operator specific optimization

For our Dynamic Optimization process, the SAP DM system will be designed to analyze each individual operator’s material weighing skills and dynamically adjust the material weight tolerances depending on previous weighing cycles for that material. The system should maintain tolerances for each operator/material combination. When the operator logs into the scale and starts the portioning process by take-off weighing for the predefined material, the system will either:

- Automatically adjust the tolerances to the values as calculated by their past performance

- Use the tolerances (T+, T, T-) as defined in the BOM. The usage of the optimized or standard tolerance setting will be set by TDO Algorithms.

II. Maintaining and adjusting the Tolerances and BOM settings for enhanced accuracy

When processing orders from SAP S4 or SAP DM, the supervisor will have the option to select an order and reassign components to the scales allocated to the production line. However, components will be automatically distributed to the scales once the order is scheduled and assigned to the production line. There will be no changes to the supervisor’s DM POD interface, as the dynamic optimization process will operate seamlessly in the background. The supervisor will, however, have access to all necessary tools and information to monitor and execute the process efficiently.

The operator will use the weighing scale terminal and interface to complete the portioning process. The operator terminal (scale indicator) should be configured to display an “immediate interactive traffic light system” that dynamically changes color based on the weight on the scale relative to the target and tolerance ranges. The status indicators will function as follows: Yellow:- Under Range; Red:- Out of Range; Green:- Accepted.

The system will continuously monitor weight measurements for each operator against the assigned target value and tolerance range, adjusting bandwidth tolerances as needed. These adjustments aim to accommodate operator-specific tendencies and variations in material characteristics while maintaining the flow, quality, and speed of production, even under seasonal variations.

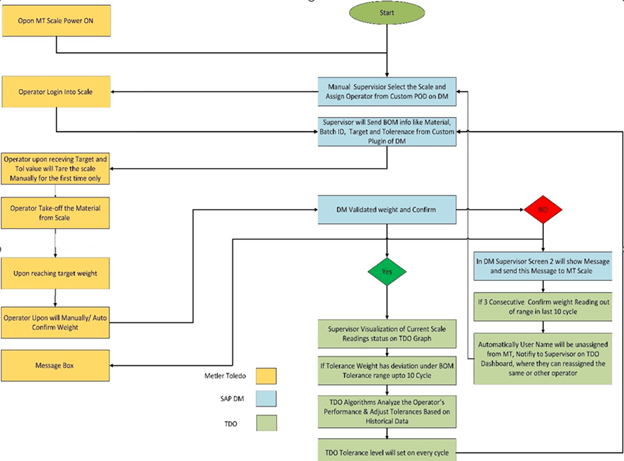

Process Flow of Portioning Scale Cycle and TDO

Process Flow Chart depicting the Portioning Scale workflow and Dynamic Optimization

I. Assigning Operators to scales in the manufacturing workflow

The Scale as an Instrument can be assigned in a agile Manner to the different operators, based on the Shifts and availability and production requirements by the Production Supervisor.

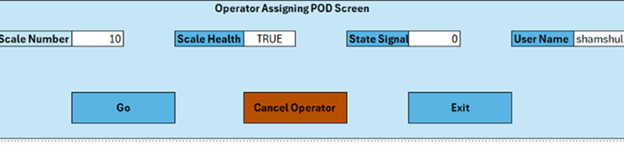

Operator Assignment POD (Production Operator Dashboard) Screen

II. Assigning materials to weighing scales in Digital Manufacturing

A form interface for assigning materials to specific weighing scales, that includes fields for entering material details, batch information, order number, storage location, quantity, scale, state signal, available quantity, and options for confirming weight, auto acceptance time delay, recipe type, and TDO/BOM with tolerance fields. This ensures precision in the weighing process.

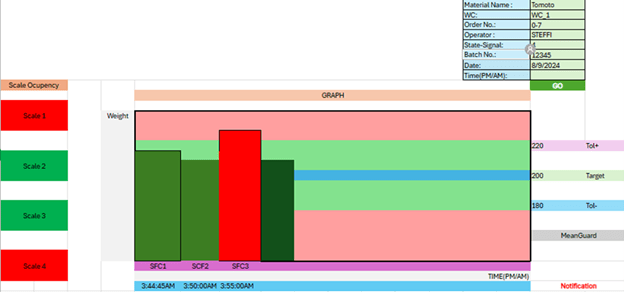

III. Real-time weight monitoring dashboard for Greenfield mega site project, KSA

With just one click on Scale tiles can monitor the graphical analysis to understand the variances in the scales for different cycles of measurement by the same operator, as shown in the screen below.

Dashboard for weight monitoring of the Tomato Batch across different cycles of specific Operator

Why This Matters for Process Manufacturing

Process manufacturing runs on precision, consistency, and compliance — especially in industries like food, pharmaceuticals, and chemicals, where every gram and every cycle matters.

By integrating SAP Digital Manufacturing (SAP DM) with Target Dynamic Optimization (TDO), Stellium enables process manufacturers to bring intelligence and adaptability directly to the shop floor.

Through this integration, manufacturers can:

- Reduce variability with real-time, operator-specific tolerance adjustments that keep every batch within specification.

- Leverage AI and machine learning to make unbiased, data-driven decisions across multiple production cycles.

- Ensure compliance and quality through dynamic BOM and recipe management aligned with regulatory standards.

- Boost efficiency via seamless connectivity between SAP S/4HANA, shop floor devices, and manufacturing analytics.

- Scale rapidly with a flexible, replicable logic that supports both greenfield and brownfield implementations.

In short, this isn’t just another smart factory enhancement; it’s a strategic evolution for process manufacturers aiming to achieve agility, traceability, and a sustainable competitive edge in fast-changing global markets.

Ready to transform your shop floor into a smart, adaptive production hub?

Stellium’s SAP Digital Manufacturing and TDO solutions are built to deliver precision, agility, and operator-specific optimization at scale. For more support, talk to our experts!