The Plant Yard Logistics Challenge

Plant yard logistics remains one of the most complex and under-optimized areas of the supply chain. Inefficiencies such as manual gate checks, floating weighment slips, dock delays, and traffic congestion create persistent bottlenecks. These inefficiencies not only drive-up operational costs but also frustrate teams and increase compliance risks.

Traditional Yard Logistics (YL) solutions require expensive licenses and often lack the flexibility to adapt to the diverse operational needs of modern plants. As plants scale, these challenges compound — making it essential to rethink yard operations with integrated, intelligent solutions.

The Business Impact of Inefficiencies

The consequences of outdated yard processes ripple across the supply chain. Common issues include:

- Delays in inbound and outbound processing

- Increased demurrage and detention charges

- Loss of audit trails and compliance risks

- Congested plant facilities leading to safety issues

- Limited visibility into dock, staging, and traffic management

These inefficiencies disrupt throughput, impact compliance, and reduce overall supply chain resilience.

Stellium’s TITO Solution: A Digital Control Tower

Stellium’s Truck-In Truck-Out (TITO) solution, built on SAP BTP and fully integrated with SAP S/4HANA and SAP EWM, addresses these challenges directly. Designed as a cost-effective and intelligent alternative to traditional YL licenses, TITO digitizes the entire yard journey — from truck entry to goods issue — enabling zero-touch automation, real-time visibility, and regulatory compliance.

This customizable framework transforms yard operations into a digital control tower, ensuring that every truck, dock, and movement inside the plant is intelligently managed.

Core Capabilities of TITO

Workflow Automation & Elimination

TITO eliminates inefficient manual workflows by automating key checkpoints:

- Auto PO validation at gate entry, integrated with SAP EWM

- Automatic creation of inbound deliveries and inspection lots

- Centralized usage decisions to accelerate quality checks

- Real-time weighment integration, instantly posting goods receipts into SAP

- Full digitization of door management, staging, OPD, pre-load verification, PO checks, and weighment slips

These automations reduce paperwork, errors, and delays, while ensuring seamless data flow from gate entry through goods posting.

Real-Time Visibility & Dashboards

TITO introduces live visibility across all yard operations:

- Truck tracking with alerts for delays or deviations

- TU & Dock Dashboards showing TU movement, dock usage, and dwell times

- Real-time dashboards for staging zones and yard allocation

- Automatic SAP EWM synchronization every five minutes to provide continuous updates on readiness, utilization, and dwell times

With these insights, managers gain the ability to make proactive decisions and optimize throughput.

Intelligent Routing & Traffic Flow

Large plants can span over 100 acres and resemble internal highways. Without proper control, congestion can cripple operations. TITO prevents these disruptions through:

- Automated traffic flow management and congestion prevention

- Dynamic routing across plant roads to avoid jams

- Prioritization of unloading-ready trucks to maximize dock utilization

Advanced Staging & Planning

To accelerate dispatch and minimize dwell times, TITO provides proactive staging and planning capabilities:

- Pre-staging of critical consignments before truck arrival

- Intelligent resource allocation for raw material tankers, PMG, and FG shipments

- Intelligent swapping to address volume shortfalls and shipment complexities

- Fast-track loading to shorten lead times and improve on-time delivery

Automation & Compliance

Zero-touch compliance is achieved through tight integration with automation technologies:

- RFID, ANPR, weighbridges, and slot booking fully integrated with SAP

- Automatic ASN generation in SAP S/4 EWM for real-time shipment visibility

- Automated dock allocation, indent verification, staging, and loading

Business Results Delivered by TITO

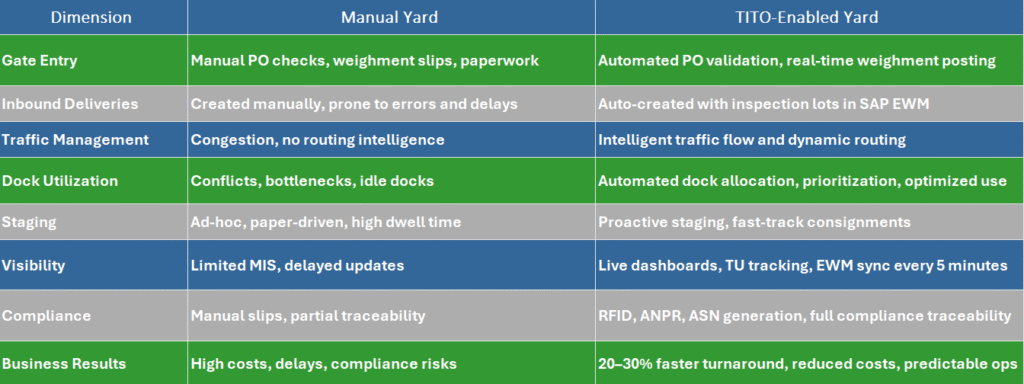

By digitizing repetitive and paper-heavy workflows, Stellium’s TITO delivers measurable outcomes:

- Truck turnaround times reduced by 20–30%

- Faster cycle completion and elimination of redundant tasks

- Optimized dock utilization and better staging management

- Improved compliance and traceability, reducing risks

- Stronger production synchronization, ensuring reliable flows

- Actionable MIS insights for predictive and real-time decision-making

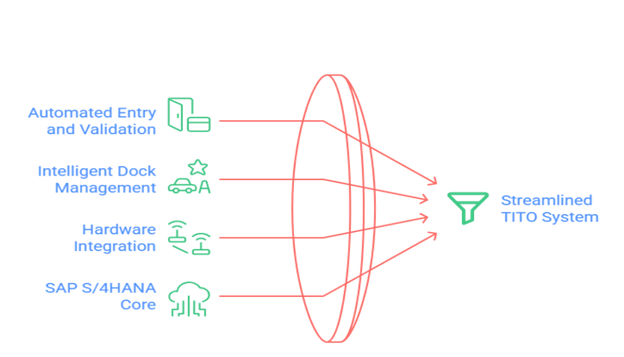

TITO Solution Architecture

At its core, TITO integrates tightly with SAP systems to enable a single source of truth for yard logistics:

- Automated Entry, Validation & Auto ASN Generation: PO validation, inbound delivery creation, goods receipt posting, and ASN generation from SAP S/4 EWM.

- Intelligent Dock & Traffic Management: Dock allocation, indent verification, slot booking, automated staging/loading, and TU dashboards.

- Hardware Integration: RFID, ANPR, weighbridges, and edge devices ensuring zero-touch automation.

- SAP S/4HANA Core: Real-time yard data flows directly into SAP EWM and SAP S/4HANA, enabling predictive analytics and centralized control.

TITO Solution Architecture

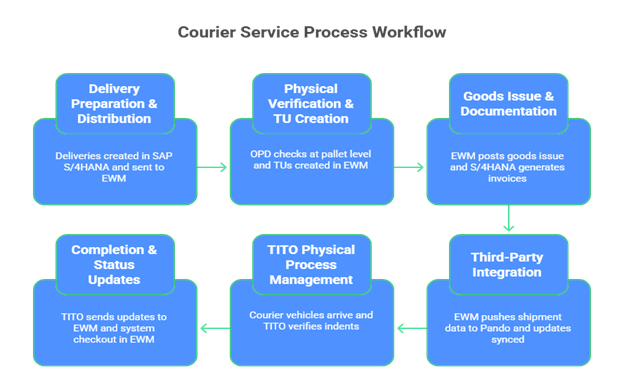

Case Study: Courier Service Workflow

For a leading courier service provider, Stellium designed a TITO-enabled workflow connecting SAP S/4HANA, SAP EWM, Stellium’s TITO framework, and third-party logistics platforms. The process included:

- Delivery preparation, distribution, and ASN generation in S/4HANA and EWM

- Physical verification, OPD checks, and TU creation

- Goods Issue posting and automated invoice/e-way bill creation

- Third-party integration with Pando for indent synchronization

- Gate verification, physical loading, and dock operations through TITO

- Completion with real-time status updates and automated checkout

This case demonstrated how TITO supports seamless integration across SAP and partner platforms, ensuring visibility, compliance, and faster throughput.

Stellium’s Flexible Approach to Indents

Recognizing that logistics is never one-size-fits-all, Stellium supports three flexible indent methodologies:

- Standard Indents: For B2B, cross-border, and high-value deliveries with full compliance.

- Truck Indents: For heavy cargo, chemicals, automotive, and temperature-sensitive shipments.

- No-Indent Methodology: For express and emergency shipments, using direct goods issue, exception scanning, and retrospective documentation.

Before vs. After: Manual Yard vs. TITO Yard

Smarter Plant Yard Logistics Start Here

Stellium’s TITO solution has enabled faster truck turnaround, reduced demurrage costs, and improved production synchronization for global customers. With real-time visibility, RFID integration, and auto-generated ASNs, organizations achieve stronger compliance and smoother collaboration across SAP, MES, and logistics systems.

Explore how Stellium’s SAP EWM and Yard Logistics specialists can tailor a roadmap for your facility.

Evaluate your current yard setup with Stellium’s Assessment Services and connect with our experts.