Verified By: Stellium’s Supply Chain Planning & Business Consulting Team, Anirban Majumdar, and Anoop Prasad

The Core of the Modern Factory

In the era of Industry 4.0, manufacturing excellence is no longer measured by throughput alone, it’s defined by intelligence, adaptability, and data-driven precision. Digital Manufacturing is the core of the modern factory. The system is self-optimizing, adaptive, and data-driven, unifying systems, people, and machines into an intelligent network that learns, evolves, and acts in real-time.

Industry Growth Signals the Digital Shift

The global Industry 4.0 market is entering a high-growth phase, projected to surge from $190.87 billion in 2025 to $884.84 billion by 2034, at a robust 18.6% CAGR. North America is leading the charge with a 20.13% CAGR, reflecting aggressive investment in smart manufacturing technologies. This trajectory underscores the strategic urgency for manufacturers to scale digital capabilities, where SAP Digital Manufacturing plays a pivotal role in bridging innovation with operational impact. Source

Let’s Discuss:

- Transforming Vision into Intelligent Execution: SAP DM Overview

- SAP Digital Manufacturing at the Forefront of Emerging Trends

- SAP Digital Manufacturing System Architecture

- How SAP Digital Manufacturing Redefines Operations

- AI for Predictive Intelligence in SAP Digital Manufacturing

- Building a Digital Manufacturing Roadmap

- Future-Ready Implementation Practices Shaping SAP Digital Manufacturing

Transforming Vision into Intelligent Execution: SAP DM Overview

SAP Digital Manufacturing (SAP DM) is a cloud-based manufacturing operations platform built on the SAP Business Technology Platform (BTP). It connects shop floor equipment, people, and business systems, enabling real-time visibility, analytics, and control across global production networks. The solution combines manufacturing execution (DMe), analytics (DMi), scheduling (REO), and collaboration (DMn) to deliver transparency, agility, and continuous improvement.

SAP DM empowers manufacturers to:

- Execute and monitor production processes with role-based, Fiori-enabled dashboards and Production Operator Dashboards (PODs)

- Integrate seamlessly with SAP S/4HANA, EWM, and ERP systems to enable end-to-end workflows, connecting Shop Floor Control Systems and IoT devices into a unified, intelligent manufacturing network.

- Automate and optimize resource allocation, labor tracking, and equipment utilization using real-time KPIs like OEE and downtime analytics

- Leverage AI, machine learning, and digital twin technology for predictive insights, real-time synchronization, anomaly detection, and adaptive decision-making.

- Enable Industry 4.0 capabilities such as edge automation, one-piece flow, and closed-loop planning

- Collaborate across stakeholders through structured issue resolution, visual content sharing, and contextualized communication

Together, these capabilities position SAP DM as a strategic enabler of smart factory transformation, operational resilience, and scalable digital innovation.

SAP Digital Manufacturing at the Forefront of Emerging Trends

The Digital Manufacturing landscape in 2025 is being reshaped by a convergence of technologies that connect intelligence, sustainability, and agility across every production layer. SAP Digital Manufacturing sits at the center of this transformation, enabling real-time adaptability and enterprise-scale decision making.

1. SAP DM 25.08 Enhancements – Realizing the Smart Factory Vision

SAP’s continuous innovation cycle is driving faster and smarter production environments. The 25.08 release introduced key upgrades like bulk component addition, extended data collection APIs, and enhanced automation flexibility, allowing manufacturers to orchestrate shop floor performance with precision.

Stellium’s in-depth analysis of these capabilities can be found in SAP Digital Manufacturing 2508 Release Highlights, which explores how these updates translate into real-world efficiency gains.

2. Predictive Digital Twins – From Monitoring to Anticipation

Manufacturers are adopting digital twin ecosystems to simulate, predict, and optimize production performance. These virtual models utilize SAP DM’s live data to predict downtime, optimize resource utilization, and synchronize physical and digital operations for continuous improvement.

3. AI and Machine Learning at Scale

Artificial Intelligence has evolved from small pilots to core manufacturing infrastructure. SAP DM integrates AI to enhance predictive maintenance, quality inspection, and production scheduling, and create self-learning factories where human expertise and data insights converge.

4. Software-Defined Manufacturing – Flexibility as a Service

The future factory is modular and software-driven. SAP DM supports this shift by decoupling hardware from control logic, allowing rapid reconfiguration of production lines without physical changes, accelerating time to market, and enabling agile responses to shifting demand.

5. Sustainability and ESG Integration – Beyond Efficiency

Sustainability is no longer a side goal; it’s a defining metric of success. SAP DM’s resource tracking and traceability tools enable manufacturers to monitor energy, waste, and emissions data, aligning operational efficiency with ESG commitments.

These evolving trends highlight how SAP DM unites intelligence and execution.

SAP Digital Manufacturing System Architecture

SAP Digital Manufacturing (SAP DM) operates as a cloud-based execution and intelligence layer built on the SAP Business Technology Platform (BTP). It seamlessly integrates enterprise planning systems with real-time shop floor operations, creating a continuous data loop between design, execution, and performance.

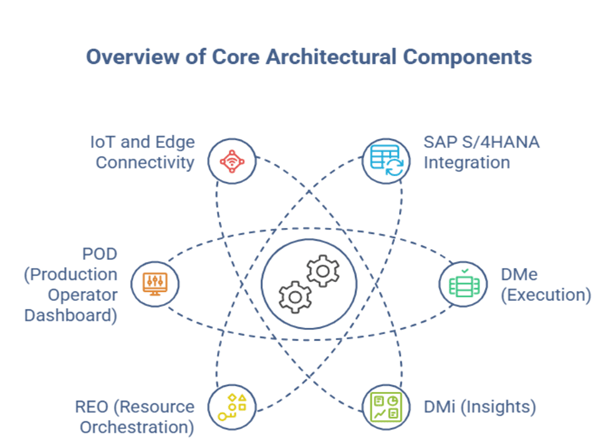

Core Architectural Components

SAP S/4HANA Integration: Ensures end-to-end process continuity from order creation to production confirmation to order completion.

DMe (Execution): Handles order dispatching, material consumption, and work-in-progress tracking.

DMi (Insights): Provides analytics dashboards, KPIs, and OEE performance metrics.

REO (Resource Orchestration): Schedules and coordinates machines, operators, and shifts dynamically, while optimizing capacity planning to ensure resource availability and production efficiency.

POD (Production Operator Dashboard): The central interface for operators, capturing data from the shop floor.

IoT and Edge Connectivity: Connects sensors, PLCs, and machines for real-time data acquisition and event management.

These layers deliver closed-loop manufacturing, where planning, execution, and analysis continuously feed one another.

Enhancing Process Manufacturing Efficiency with SAP Digital Manufacturing

SAP Digital Manufacturing supports both discrete and process manufacturing environments. Whether assembling automotive components or managing batch production, SAP DM provides unified visibility and control, capturing data at every production layer and translating it into actionable intelligence for continuous improvement.

Enabling end-to-end digital continuity for manufacturers across all verticals, SAP DM delivers:

- Continuous or batch-based production monitoring with full traceability.

- Recipe management and yield optimization to maintain consistency and minimize waste.

- Parameter-based quality control tracks variables like temperature, viscosity, and pressure in real time, enhanced by fully automated visual inspection.

- Regulatory traceability and compliance reporting, ensuring standards are met across every production stage.

How SAP Digital Manufacturing Redefines Operations

SAP DM brings the power of digitalization directly to the shop floor. It provides a low-code, fully configurable MES platform that connects the shop floor to the top floor, ensuring process integrity, synchronization, and visibility across the entire value chain.

When organizations plan their transformation, it’s vital to select a platform that meets current needs while future-proofing for innovation. SAP DM enhances control, integration, and execution while enabling global data visibility and analysis.

Key Capabilities That Redefine Modern Manufacturing:

- End-to-End Visibility: Real-time tracking of production, material flow, and performance metrics across global plants, creating one version of operational truth.

- Integrated Intelligence: Seamless data exchange between SAP DM, ERP, and supply chain systems empower faster decisions and predictive insights.

- Scalable Automation: Low-code workflows and machine integrations enable rapid deployment of new processes while reducing dependency on legacy systems.

AI for Predictive Intelligence in SAP Digital Manufacturing

Predictive Manufacturing uses machine learning, IoT data, and advanced analytics to anticipate outcomes, turning every production line into a learning system that drives continuous improvement. By combining machine learning, IoT data, and production insights, SAP DM helps enterprises shift from reactive to proactive operations, turning every production line into a predictive ecosystem that continuously learns and improves.

In SAP Digital Manufacturing, predictive intelligence ensures processes evolve based on performance insights rather than static plans.

Key Impact Areas:

- Predictive Maintenance: Identify potential failures before downtime occurs, improving reliability, and reducing maintenance costs.

- Production Forecasting: Adjust schedules dynamically based on real-time data to match demand fluctuations with precision.

- Quality Assurance: Detect deviations early and automatically correct process parameters to uphold product consistency.

- Energy Optimization: Analyze consumption trends to enhance sustainability and operational efficiency.

SAP DM’s AI-driven analytics unify machine data, planning intelligence, and production visibility, enabling continuous improvement beyond traditional automation.

See real-world examples of SAP DM in action to achieve manufacturing excellence with SAP Digital Manufacturing. Manufacturers from multiple industries showcase how SAP DM drives digital transformation.

As organizations expand these digital capabilities, the need for agility and intelligence becomes the defining force, shaping the next wave of transformation. Once the roadmap is set, manufacturers can harness AI to anticipate performance, prevent downtime, and continuously optimize operations, bringing predictive manufacturing to life.

Building a Digital Manufacturing Roadmap

Digital Manufacturing success is rooted in execution. A well-defined roadmap identifies processes, data flows, and readiness milestones before implementation. Stellium’s proven approach helps enterprises transition from concept to reality, defining governance frameworks, data strategies, and changing management models that ensure lasting transformation.

Stellium empowers process manufacturers to accelerate transformation with a structured, scalable approach, backed by 11 pre-built accelerators tailored for the industry. These plug-and-play solutions are easily configurable for any customer, dramatically reducing implementation time and complexity.

To dive into Stellium’s readiness and deployment strategy and to transform with confidence!

Download Stellium’s SAP DM Assessment Brochure

Here’s how it works:

- Clear Objectives: Define KPIs, quality, and productivity goals for measurable outcomes.

- Digital Readiness: Assess systems, data, and connectivity to close performance gaps.

- Governance Alignment: Unite IT, operations, and leadership for accountable transformation.

- Scalable Design: Use SAP DM’s low-code, modular architecture to enable continuous innovation.

Learn how to build your Digital Manufacturing vision with our proven framework.

Future-Ready Implementation Practices Shaping SAP Digital Manufacturing

Digital transformation in manufacturing is no longer about simply going live, and it’s about building systems that evolve with changing technologies, supply chain conditions, and sustainability goals.

Modern SAP DM implementation strategies are focused on resilience, adaptability, and measurable performance from day one.

AI-Driven Roadmaps: Implementation frameworks increasingly leverage AI to forecast resource needs, predict disruptions, and guide phase sequencing for maximum ROI.

Composable Architecture: Modular and API-first design enables continuous innovation, allowing manufacturers to scale individual capabilities without system overhauls.

Sustainability-Embedded Design: Energy use, emissions tracking, and waste reduction KPIs are now integral to every implementation milestone, not post-deployment add-ons.

Digital Twin Readiness: Manufacturers validate workflows and performance outcomes in digital twin environments before roll-out, reducing go-live risk and downtime.

Human-Centered Change Enablement: Beyond technology, success depends on empowering people through upskilling, AI-assisted workflows, and collaborative planning between IT and operations.

Partnering with Stellium: Transform with Confidence

Stellium enables clients to future-proof their operations through innovation, efficiency, and resilience. Whether you are transitioning from legacy MES or planning your next-generation factory, Stellium provides the strategic and technical foundation to make it happen. Learn more about the differences between MES and SAP DM

Ready to build your digital future?

Our experts will help you design, implement, and scale intelligent factory solutions that drive measurable efficiency, agility, and growth. Explore SAP DM Solutions | Talk to an expert!

The original LinkedIn article is updated and expanded to include Stellium’s latest findings, release highlights, and trends.