Verified By: Stellium’s Supply Chain Planning & Business Consulting Team, Anirban Majumdar, and Anoop Prasad

Manufacturing transforms raw materials into finished goods through structured steps. While discrete manufacturing assembles individual items, process manufacturing focuses on producing bulk goods like chemicals, food, or pharmaceuticals, where precision and consistency are critical. This is where SAP Digital Manufacturing plays a vital role in ensuring efficiency and control.

Why Process Manufacturers Need a Smarter Solution Digital Core

Process manufacturing for spanning industries like chemicals, pharmaceuticals, and food and beverage demands precision, compliance, and agility. While SAP S/4HANA acts as the digital core that connects business planning with manufacturing execution, Industry 4.0 technologies like SAP DM bring that intelligence to life on the shop floor.

SAP Digital Manufacturing is not merely a Manufacturing Execution System (MES) it is a foundational Industry 4.0 platform that drives smart, connected, and autonomous manufacturing across enterprises.

Together, they create a closed-loop system forming the intelligent backbone of modern manufacturing, integrating people, processes, and data across the enterprise. This blog highlights how SAP DM enhances quality, efficiency, and visibility across every process.

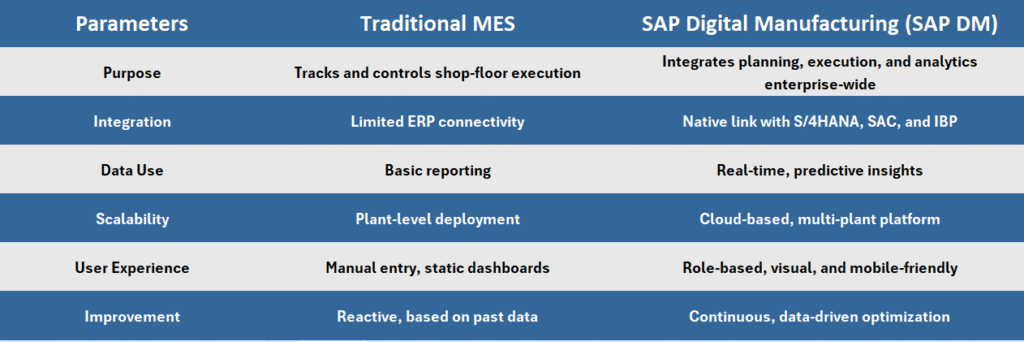

Below is a comparison table to understand how SAP Digital Manufacturing goes beyond a traditional MES (Manufacturing Execution System).

Current Challenges in Process Manufacturing Industry

Process manufacturers today face persistent challenges that limit productivity and profitability. While the demand for precision and compliance rises, legacy systems and fragmented data hinder real-time decision-making and operational agility.

Key challenges include:

Raw material variability: Inconsistent input quality affects yield and product uniformity.

Complex compliance demands: Strict regulatory requirements create heavy documentation burdens.

Limited visibility: Siloed systems make it difficult to track performance across sites and processes.

Manual processes: Paper-based reporting and disconnected tools slow down responses to issues.

Operational inefficiency: Unplanned downtime, maintenance delays, and forecasting gaps increase production costs.

Addressing these challenges calls for an integrated digital foundation, one that connects planning, execution, and analytics in a single intelligent system.

Key Capabilities of SAP Digital Manufacturing for Process Manufacturing

1. Batch & Recipe Management

Ensure end-to-end traceability and control of formulas, batches, and recalls. SAP DM supports Electronic Batch Record (EBR – Beta version) functionality, which is especially critical for pharmaceutical and chemical industries. EBR ensures secure, digital documentation of batch processes, improving traceability, compliance, and audit readiness.

This functionality, based on SAP’s beta-tested results, provides measurable efficiency benefits for pharmaceutical and chemical industries, improving batch release accuracy and reducing manual documentation steps through automated EBR tracking.

SAP DM enables precise version management and execution of recipes, maintaining consistency across shifts and production runs while reducing manual errors. Built-in genealogy tracking simplifies audits and regulatory compliance.

2. Integrated Quality & Compliance Management

Detect, prevent, and resolve quality deviations in real time. SAP DM connects sensors, process parameters, and inspection results, automatically triggering alerts or corrective actions before non-conformities occur. This ensures compliance with FDA, GMP, or ISO standards — critical for food, pharma, and chemical operations.

3. Adaptive Production Planning & Scheduling

Go beyond static schedules with real-time synchronization of demand, capacity, and resources. By integrating SAP DM with SAP S/4HANA and IBP, planners can dynamically adjust production based on shop-floor feedback, reducing downtime, waste, and inventory imbalances.

The Resource Orchestration (REO) feature further enhances adaptive scheduling by optimizing workforce allocation and resource utilization in real time. As a cloud-based scheduling tool, REO empowers production supervisors to control shop-floor operations and monitor events in real time, making quick adjustments to resources to keep equipment, personnel, and materials aligned for optimal throughput.

4. Process Analytics & Continuous Improvement

Leverage embedded analytics to monitor OEE, yield, and cycle-time metrics. SAP DM consolidates machine and operator data into actionable dashboards, empowering teams to identify bottlenecks and drive continuous improvement initiatives with data-driven precision.

Integrating SAP Digital Manufacturing (DM) and SAP Analytics Cloud (SAC) delivers predictive, executive-ready insights across batch performance, quality, and production efficiency. SAC extends SAP DM’s analytics by visualizing real-time data, supporting audits, and enabling natural language queries through its ‘Just Ask’ feature enhancing accessibility for non-technical stakeholders. Learn more about SAP Analytics Cloud for Advanced Manufacturing Insights.

5. IoT-Driven Equipment Integration

Connect machines, PLCs, and sensors directly to SAP DM to gain real-time visibility into production performance. IoT connectivity enables predictive maintenance, anomaly detection, and condition-based interventions that keep equipment uptime high and costs low.

6. Sustainability & Energy Efficiency Insights

Measure and optimize energy, material, and water usage across production lines. SAP DM’s analytics layer helps organizations benchmark sustainability KPIs, enabling greener manufacturing and reduced operational footprints.

Inside a Real Process Manufacturing Transformation with SAP DM

Process manufacturers using SAP DM report faster cycle times, fewer quality incidents, and stronger regulatory readiness. In pharmaceuticals, electronic batch records (EBR) simplify audits; in food and beverage, recipe control ensures product consistency; in chemicals, predictive maintenance minimizes downtime. Together, these outcomes translate into measurable gains in efficiency, quality, and trust.

Stellium Transforming Food Production with SAP Digital Manufacturing.

A major food producer faced growing complexity in its process manufacturing setup.

High costs, long lead times, and limited shop-floor visibility slowed performance and reduced efficiency.

With SAP Digital Manufacturing (SAP DM), the company turned these challenges into an advantage.

By integrating SAP DM into their existing SAP S/4 system, they gained real-time visibility, automated production control, and smarter quality management.

The result? Faster insights, better outcomes, and a modern manufacturing floor built to grow.

Download the Stellium case study to see the success story of real-time visibility and efficiency with SAP DM. How Stellium’s Accelerators Lead Process Manufacturing Transformation

Stellium drives measurable results by helping process manufacturers transform with speed and precision. Its 12 purpose-built accelerators are designed exclusively for the process industry, giving teams plug-and-play tools that adapt to any environment. Each accelerator shortens implementation cycles, simplifies deployment, and fast-tracks success with SAP Digital Manufacturing.

Get the Assessment Brochure and unlock Stellium’s SAP DM advantage with a free assessment from our experts Building an Intelligent, Predictive, and Sustainable Future for Process Manufacturing

As digital technologies evolve, manufacturers move beyond basic automation anticipating challenges, adapting in real time, and continuously optimizing performance. By integrating IoT sensors, digital twins, and AI-driven analytics, these solutions enable data-driven operations that minimize waste, ensure quality, and advance sustainability across the connected supply chain.

Transform Your Process Manufacturing with SAP Solutions

SAP Digital Manufacturing, integrated with SAP S/4HANA, provides the intelligence and agility process manufacturers need to thrive in the Industry 4.0 landscape. By uniting people, processes, and technology, it transforms production into a connected, compliant, and continuously improving ecosystem.

Let’s transform your process operations together. Connect with our experts, to learn how to streamline your production, strengthen compliance, and deliver measurable outcomes.